ETCHING MATERIALS FOR

Our innovative high viscosity paste fills an unmet need

The Navy needed a safer and more efficient alternative to the hazardous process used in traditional non-destructive inspection (NDI) processes to test aircraft components for cracks and corrosion. ANI’s solution, which has been successfully tested on Naval aircraft materials, has the high viscosity of toothpaste, comes in single-use packets, has a long shelf life, and gets the job done more effectively and safely.

Safer

More efficient

Single use,

Easy storage

Our three-packet kit: safe, convenient, effective

The traditional method involves dipping aluminum alloys in large baths of corrosive etchant materials which are difficult to contain, may damage other components, and could expose users to chemical burn. Our high-viscosity materials are contained in a three-packet kit (etchant, neutralizer and de-smut) for single-use application, and can be used as-is with no mixing.

More revealing than traditional processes

Far from compromising performance, the increased viscosity ANI solution has demonstrated improved etch-rate. It achieves 0.5 micros/min etch rate at <30° C and uncovers cracks more visibly than with traditional methods. An added advantage is the shelf-life of <12 months. Packets maintain their integrity under weights of 25lb.

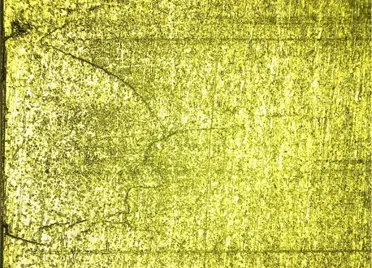

Quench-cracked aluminum after sanding with 600 grit. Metal is smeared and cracks are hidden.

Quench-cracked aluminum after sanding and after ANI etch. Cracks are uncovered by etch!

UV penetrant test on quench-cracked sample after etch with ANI materials.

A Navy-tested product with broad applications

Penetrant NDI is important for early detection of corrosion and structural damage before component failure. The ANI solution has been successfully tested for use on Navy aircraft, but similar NDI needs are found on commercial aircraft, oil and gas exploration, refineries and pipeline transportation, ocean cargo vessels, railways, and aluminum industries in general.

Let’s make small talk for LARGE IMPACT

Contact us to discuss how our nanotechnology innovations can meet your goals and challenges.